1. Project background

Precipitated calcium carbonate (or light CaCO3, PCC for short) is one of the important raw materials for the production of high-permeability packaging paper, cigarette paper and other special papers. The quality of special paper is directly related to the properties and quality of calcium carbonate. For example, with the progress of society, it is necessary to reduce the content of harmful substances in cigarettes. In order to fully burn the cut tobacco, the use of high-permeability cigarette paper is a more effective method. At the same time, with the advancement of cigarette production technology, the speed of cigarette making machines has greatly increased, and cigarette papers are required to have higher strength to adapt to high-speed cigarette making machines. Therefore, high-strength, high-permeability cigarette papers are very popular among cigarette manufacturers. In 2018, my country’s cigarette paper was 260,000 tons, of which about 130,000 tons were used to produce low- and medium-tar content cigarettes, namely high-end cigarette paper. Based on the 30-40% calcium carbonate in cigarette paper, the annual demand is in cigarette paper The medium demand for calcium carbonate is about 90,000 tons, of which the high-quality calcium carbonate required for high-end cigarette paper is about 50,000 tons. Annual production of 1,000 tons of nano gas phase titanium dioxide project Annual production of 20,000 tons of special paper special light calcium carbonate project

2. Product description

The role of calcium carbonate in cigarette paper is: (1) Increase the refractive index, so that the tobacco does not show the background color, which is an important indicator of cigarettes. (2) Adjust the burning speed to adapt the burning speed of the cigarette paper to the cut tobacco, and keep the cigarette burning without extinguishing the flame. (3) Make the ash of the burned cigarette paper adhere firmly to the shredded tobacco and pack the ash. (4) Increase the whiteness of cigarette paper. (5) Make the cigarette paper have higher air permeability to reduce its tar content. To improve the air permeability of cigarette paper, in addition to using reasonable raw materials (fiber ratio) and beating technology, the amount of filler can also be appropriately increased. But as the amount of filler increases, the tensile strength of the paper also decreases. Therefore, it is particularly important to develop special calcium carbonate with certain characteristics that can not only increase the air permeability of cigarette paper, but also maintain or minimize the strength of the paper, and it is mainly necessary to meet the "double high" (high strength, high air permeability) of the finished paper. )performance. After adding light calcium carbonate to cigarette paper, it can increase the opacity, whiteness, feel and softness of the paper, improve air permeability, and adjust the burning speed of cigarettes. Ordinary domestic light calcium is distributed in sheets on cigarette paper due to unreasonable particle shape and particle size. The calcium carbonate flakes cover the space between the fibers in the paper. The uncovered fibers have high air permeability, which is easy to cause poor air permeability. Uniform and unstable, and the paper feels thinner and has poor refractive index. This product is special calcium carbonate for high-end cigarette paper. It can be distributed on the paper with a three-dimensional effect. There are channels between calcium carbonate crystal particles and cannot prevent air from passing. It ensures the uniformity and stability of the cigarette paper's air permeability. The paper feels thick and thick. It is soft, has high refractive index and air permeability, and has good performance. The performance is comparable to imported products. At the same time, compared with imported products, the price is greatly reduced.

3. Project raw materials

Calcium oxide: chemical formula is CaO, white block (or powder), purity ≥95%, particle size 100-150 mesh.

Annual production of 1,000 tons of BIPB (odorless DCP) project

4. Project supporting

Industry goes to the park: supporting thermal power plants and paper mills.

5. Product benchmarking

Benchmark similar products in the United States and Germany.

6. Safety and environmental protection

This project has no hazardous chemicals and hazardous processes, and zero emissions of the three wastes.

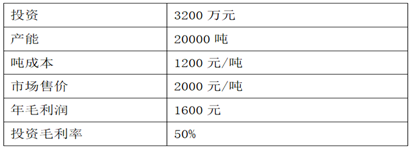

7. Project investment

30 million yuan

8. The project covers an area of 10 acres

9. Economic benefits