We provide customers with full-process solutions from feasibility study, technical scheme design, process package design, detailed design, equipment supply, and start-up debugging. We focus on cultivating long-term customer relationships, and accompany the growth of customers with excellent quality and consistent dedication. We firmly believe that quality and efficiency are reflected in the smallest details: engineering design, research and development experiments, equipment production or commissioning. At every stage of your project, we will pay attention to it.

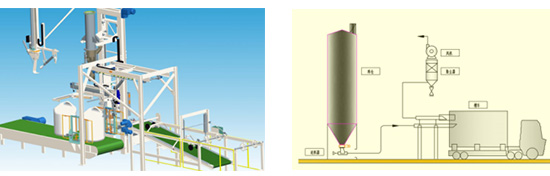

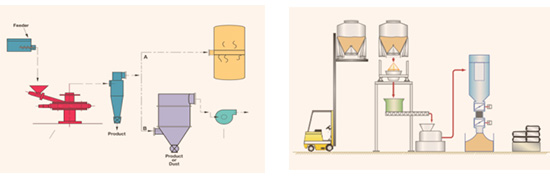

Powder transportation

Positive pressure dilute phase conveying system, positive pressure dense phase conveying system, negative pressure dilute phase conveying system, negative pressure dense phase conveying system, combined positive and negative pressure conveying system, etc.

The transportable materials include washing powder, silica sand, glass ingredients, sugar, powdered sugar, fine meal grains, coffee beans, plastic granules, bentonite, cement, starch, quartz powder, ball clay, kaolin clay, zinc oxide, granulated carbon Black and alumina, flour, sugar, salt, rice grains, iron oxide, coffee beans, pinto beans, flour, refined chemicals, etc.

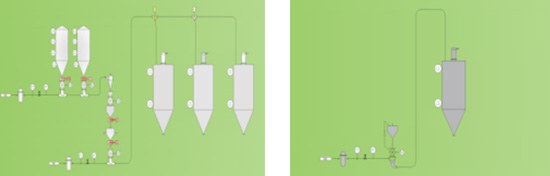

Powder drying system

It has relevant design schemes and patents for airflow drying system, fluidized bed drying system and kiln drying system.

Dryable materials include ABS resin, polycarbonate, terephthalic acid, polypropylene, polyethylene, propylene resin, feed, soybean meal, sugar, salt, L-lysine, sulfite, sulfur, nitrate, Copper sulfate, sub-refined sodium, calcium chloride, potassium carbonate, sodium carbonate, urea, coal, etc.

Powder metering and feeding system

The company has related design schemes and patents for various powder and liquid material metering systems.

It can realize the fully automatic and accurate measurement of powder conveying and feeding.

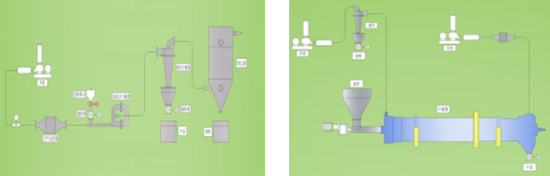

Powder crushing system

The company has related design schemes and patents for the jet mill system.

Uses: 1. Battery materials such as Ni, Co, Mn, Li, 2. Inorganic materials such as alumina, zirconia, silica, activated carbon, 3. Resin-related materials, 4. Medicines, Chinese medicine, health food, food, food additives , 5. Decomposition and classification of secondary aggregates.

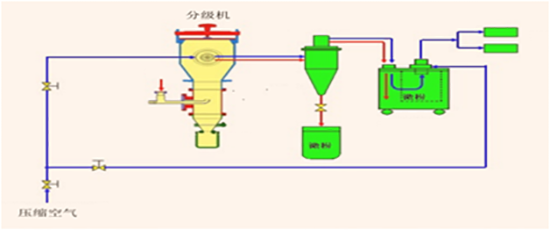

Powder classification system

The company has relevant design schemes and patents for the ultrafine powder classification system.

Uses: 1. Metal oxides and ceramics such as battery materials, 2. Resin, rubber, etc., 3. Fillers such as calcium carbonate, 4. Inorganic materials such as carbon and glass, 5. Food and medicine.

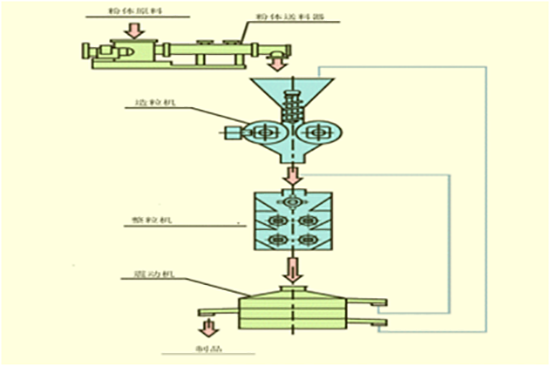

Powder compaction granulation system

The company has relevant design schemes and patents for the compaction and granulation system of superfine powder.

use:

1. Improve the efficiency of powder bagging and storage;

2. Improve the capacity of the powder granulator;

3. It is suitable for increasing the volume specific gravity of a wide range of powders;

4. Chemical industry: plastic related;

5. Electronic relations: battery raw materials (positive electrode and negative electrode), EMC, toner, paint related;

6. Medical relationship: Chinese medicine, antibiotics, etc.;

7. Seasoning, food-related seasoning;

8. Pesticides and fertilizers: lime, potassium chloride, salt, fertilizers, pesticides, herbicides.

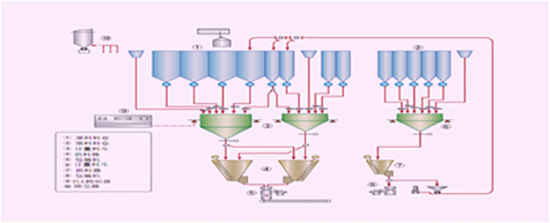

Powder packaging system

According to the powder characteristics, the packaging design can realize:

1. Packed in positive and negative pressure paper bags.

2. Packed in large bags with positive and negative pressure.

3. Tank truck packaging.

4. Container bag packaging.

5. Pneumatic unloading of tank trucks and container bags.