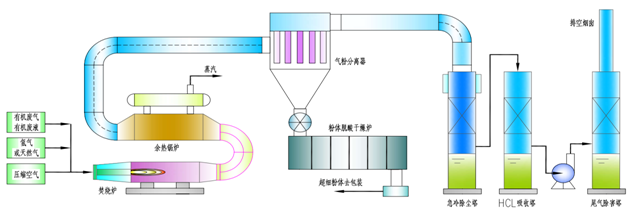

1. Technical application

It is used for the harmless treatment of organic waste gas and waste liquid from the by-product of organosilicon, while recovering HCL gas and by-product ultrafine powder sio2

2. Technical characteristics

・The high-efficiency gas-liquid integrated burner independently developed by our company makes the structure of the incinerator compact.

・The incinerator can treat all kinds of chlorine-containing organic waste liquid and waste gas. The high-performance and high-performance atomization nozzle can instantly vaporize the waste liquid, and the organic matter can be oxidized and decomposed efficiently.

・There are many options for combustion-supporting fuels: use waste oil, hydrogen, and natural gas.

・Control the combustion temperature and exhaust gas temperature to suppress the production of nitrogen oxides and dioxins.

・Reaction waste heat waste heat boiler, which can produce steam

・Through the quenching tower, the produced powder is sent out.

・The acid gas absorption tower absorbs the by-product HCL gas, produces 31% hydrochloric acid, and recovers the CL and H elements.

Because the recovery of the produced powder requires certain quality requirements for the incineration raw materials (organic gases and liquids); more precise control of the incineration reaction process is required.